This article explains the basics of home electrical wiring and its symbols. There is also a simple guide on what to check at the end of the post.

However, this is a long article. If you can see what you are looking for at the RELATED ARTICLES section below, you may want to visit that post first.

============================================

RELATED ARTICLES:

Simple house electrical layout drawing

============================================

If you come again to this post in future, you may find that the above RELATED ARTICLES section have more titles added to the list.

I am currently re-constructing this blog to make it more presentable and to add more content to it. The original article below is too long and too messy. Many visitors just click away thinking that they will not find the contents they were looking for here.

So I am now posting small topics of the content s that have been covered by the original post. It will take some time and many small posts to cover it all because it is a really long post.

However, if you wish you can still read the original article below:

-------------------------------------------------------------------------------------

Original version:

-------------------------------------------------------------------------------------

This post will explain the basics of home electrical installation wiring, the electrical symbols used in a simple house circuit diagram, and finally a simple checking that can be done to the electrical installations at home.

All these are very important to ensure that ordinary persons understand enough about the basics so they can use the electricity at home or at the office safely, and recognize the dangers and the electrical hazards when these dangers present themselves.

Content outline:

Section A. House wiring brief

Section B. Sample electrical installation for a simple house

Section C. Simple checking

CONTENT:

SECTION A: House wiring brief

This post provides some brief description of home wiring with the help of a few pictures. This time it will be just a basic description, a skeleton that can provide a structure for my future posts on this topic. Future post will explain in more details.

The electrical current that goes into our home comes from the electricity supply company's distribution network, usually in the form of overhead cables running on concrete poles or using cables buried one meter below the ground (See Picture 1.)

When the cables reach a residential house, they usually enter the house through the front entrance and connect to a meter panel (See Picture 2). Together with the meter on the panel is also a cut-out fuse and a neutral link. The meter and the fuse usually belong to the supply company.

From the meter panel the electrical cables go to the home electrical panel. On the panel is usually an isolation switch, a leakage protection circuit breaker and a few outgoing fuses or outgoing circuit breakers (See Picture 3).

From the outgoing fuses or circuit breakers the wiring cables run above the ceiling, concealed inside or on the surface of the wall, or concealed inside the concrete floor to go the lamps, ceiling fans, socket outlets and other equipment like the toilet exhaust fans in our homes.

When a home user connects an electrical appliance to a socket outlet, the connection is usually made by the use of an electrical cord. One end of the cord has a plug unit (sometimes the plug unit contains a fuse) that is inserted to the power socket (i.e. wall plug). The other end will be plugged to another socket already built-in on the appliance.

Now and then the location of the electrical appliance needs to be quite a few meters away from the wall socket outlet. The electrical cord provided with the appliance is usually between one to one and a half meters long. In these cases home users usually purchase an extension cord to connect between the wall socket and the appliance's electrical cord (Picture 4 shows an example of electrical extension cords).

From the viewpoint of the electrical current flow, the supply uses only two wires. That is why in some countries or regions we can see only two big wires coming down from the electric pole to a house. One of them is called the live wire, "hot" wire or phase wire. It is this wire that is "dangerous".

The second wire is called the neutral wire or the "return" wire. The electric current flow into the house will come out again (i.e. return) in the same magnitude and goes back into the supply company's transformer or generator. This electrical path forms a complete "loop", like a circle. The continuous and circulating flow of this electrical current is what makes the filament inside the house incandescent lamp burns and produce light that brightens our house.

This behavior of the home electrical system, when used and handled properly, makes the electricity very useful. It is however very powerful and dangerous, and therefore it must be treated with sufficient care and respect.

With the incoming two wires described above, we can have a running electricity in our home to keep the food fresh in the refrigerator and to replace the candles or other fires as the source of light during the night.

However with just these two wires, it is like driving a car at high speed without the brake. Driving the car without a brake is extremely dangerous even on an empty freeway that has no traffic light for hundreds of kilometers at three in the morning. As in driving, we need to step on the brake now and then to slow down, or during an emergency.

In a home electrical wiring system, this braking is accomplished through a third wire, the earth wire. Many electrical terms are commonly used for this wire such as earthing wire, ground wire, chassis wire or protective wire. In a house, this earth wire is almost always colored green or green with yellow stripes. The wire connects the metal casing of the electrical appliance in our homes to the "earth body". (Really, it is actually connected to the huge mass of the earth.)

Visit this post, Home electrical earth installation, to know more about the grounding of house electrical wiring.

When the "hot" or live wire somehow come into contact with the outer metal casing of your washing machine, for example, then the fuse at the distribution board will immediately blow, stopping the current flow to the metal casing of the washing machine so we do not get the shock, a fatal shock actually. Where the distribution board uses a circuit breaker instead, the circuit breaker immediately trips, cutting off the supply just like the fuse does.

If the green wire is broken, or it does not connect properly along its path to the earth body, then the electrical power has no brake. The person touching the washing machine's metal casing can get electrocuted.

So do treat the electrical wiring and electrical appliances in your home with respect. Safety comes first.

Picture 1 - Incoming electricity supply cables on concrete poles

Picture 2 - Supply authority's meter panel at house entrance or main door

As you can see, the cable coming from the concrete pole is a twisted two-core cable. Two-core means there are actually two lengths of cables in the cable set and they are twisted around each other. The twisting construction of the cable is primarily to make it better to handle, more flexible to bend around and also make it to install on to of the electric poles.

Observe that the cable run along the terrace houses just below the ceiling at the external front wall of the terrace houses. That cable is run from unit to unit until the last unit of that row. That's why you see in Picture 1 that the cable drops from the concrete pole to only the first house unit in that row. This technique reduces the number of the concrete poles required thereby reducing the construction cost and much improve on the unsightly view of the electric poles.

The energy meter is located approximately near and above the main door, just outside the house. The utility company's meter readers can read the meter every month without disturbing the house tenants. The meter you see in the picture is one of the conventional types. The meter reader needs to get close enough to be able to visually read the meter reading.

However nowadays a hi-tech type of meter is getting more popular. I will provide you with a picture of this type soon. The new type is more like a remote control kind of thing. The meter reader does not need to read the energy meter visually. He carries with him a handheld unit the size of a walkie-talkie. In front of the house main gate he just points the device towards the meter unit and presses the "read" button. The data of the meter is transmitted automatically to the handheld unit, and the latest energy bill is immediately issued to the home customer. He does not have to open the house main gate to get close enough to the meter on the wall to read it.

Back to the meter panel. The supply is tapped off from the horizontal cables, and run down to black components near the meter. One is the service fuse and the other is the "Neutral" link. The meter is separated from the incoming supply by these two components. So when you do not pay the electricity bill, the company takes off the service fuse and takes it back to their office. So the electrical circuit is broken on the "Live" side, cutting off the supply. The good news is your electric meter will not go up any more.

From the meter unit, two wires will connect the meter to the consumer electrical panel inside the house, which is also called the consumer unit (C.U.)or distribution board (DB). You cannot see the connection between the two because connection to and from the meter is done inside the wooden panel that is used to mount the meter, fuse and the neutral link. From behind the wooden panel the cables run concealed inside the wall to the electrical panel. The cables can actually be run on the wall or ceiling surface, but in the example inside the pictures, they are run concealed inside the walls.

Picture 3 - Home electrical panel

This is the front view of the consumer electrical panel with the transparent front cover open. It is usually located near the front main door of the house, not far from the energy meter. This is the case in most small houses. However, for big houses, the panel may be located inside storerooms or the small bedrooms. This is more common for houses with three-phase supply, where the maximum demand is above approximately 10 kW depending on which country you are in.

In the above example, you can see in Picture 2 that the electrical panel is located only about three meter from the energy meter. This location is not chosen by chance. When the power trips, then there may be total blackout inside the house. Locating near the front door may give some outdoor light to help the house occupants check the panel.

The panel in the picture is called a 12-way panel, or 12-way DB. The number 12 is the number of outgoing circuit breakers to serve the household final circuits. An outgoing circuit breaker is selected to protect the wiring cable of the final circuit it is serving. It is not intended to protect the electric appliances connected to the circuit. Fuses are also used to serve the same function with the advantage of cheaper maintenance because rewirable fuses are available. However, the circuit breakers are more convenient because no replacement part is necessary to put the tripped circuit back into operation after the fault have been identified and isolated, or repaired.

Note: The understanding and appreciation of all the parts and components inside the electrical panel is most important for a beginner who wishes to fully understand a house wiring system.

The black component at the left end is the isolator switch (also called the Main Switch). It is used by the occupant to manually isolate the supply into the house before any repair or maintenance work is carried out to the wiring. It is actually a switch with a fuse carrier integrated into the switch. This fuse serves as a backup overload and overcurrent protection that can cut-off supply if all other protections fail. The service fuse on the meter panel belongs to the utility company and the house occupants are not supposed to touch that fuse. Of course, they can actually take out that fuse to de-energize the wiring to the whole house. (Remember that the short stretch of cables between the isolation switch and the meter is still "live' after the Main Switch has been turned off.)

Between the isolator and the first MCB is the earth leakage circuit breaker (ELCB) or the residual current circuit breaker (RCB). This component provides the protection of the occupant from electrical shock. If there is any defect occurs at any part of the wiring that can cause the electrical current to leak out of the intended path, then it is a shock hazard. Persons who come into contact with the location where the leak is present can get an electric shock or electrocuted. The term electrocution is usually used to describe the fatal electric shock, which results in the death of the victim.

Other than the above components, there are other components not visible without opening a few screws. I do not have the digital images of these parts now (you will be able to see them soon). But if you see other posts about electrical panels on this blog, you will be able to see them very clearly. Even though they are not house electrical panels, the functions and purposes of these parts are the same. In fact you will understand them even better because they are designed to be much more reliable and tougher, and cost more money.

Picture 4 - Electrical extension cords

Picture 5 - Electrical appliances connected to wall socket

Well, this is not an example of good habits in using electricity in your kitchen, but in the city where I am living now it is a common habit. That is why I have chosen this picture to show you.

For those involved in designing the electrical wiring for house kitchens, "Please put enough sockets in the kitchen." Because the users will eventually do what they need to do to make their lives more practical. Most do not have the technical instinct to really know all the dangers from what they are doing with regard to electrical hazards at home.

Especially at home, the users come from all ages, from the few years old to the hundred year olds. It is unreasonable for the kitchen designers or electrical designers to put insufficient number of socket outlets and expect the occupants to not use extension cords as part of the permanent wiring.

Do a good job, and you will actually save lives. Let us all do our part to reduce those figures in the published annual statistics of home electrical accidents.

Picture 6 - The green "earth wire"

SECTION B: Sample electrical installation for a simple house

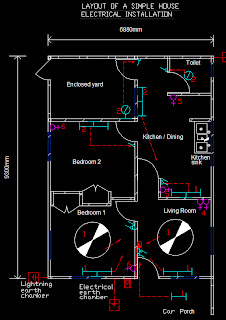

This section will provide you with an actual sample of a typical electrical installation for a small house. The purpose of this section is to answer the requests from a few readers who need a sample of typical electrical installation that is simple enough for them to understand without having to learn too much technical basics.

Basics of electrical engineering can be overwhelming to some people. Some just do not have enough spare time to learn even though they fully understand that some knowledge of a few electrical basics and skills can mean between life and death of electrocution or home fires to their loved ones.

So I present to you the following two diagrams and a schedule of symbols and legends. These three will help you understand what a house electrical installation is.

Do not be deceived by the simplicity of the small installation represented by the drawings. A huge bungalow with twenty rooms will be just as easy to understand once you understand the electrical installation for this two-bedroom single-unit house.

The design is actually an old design for single unit teacher’s quarters in rural areas. It has been used for more than forty years throughout this country. Thousands of units have been electrified with this design and many of them are still in operation today. Of course throughout this period many have been upgraded and new wiring put into place. But they still use the same basic design.

The design was done during the time when the electricity was a new way of life for the people here. The electricity was generally used for just a few basic purposes. That is why you see the number of socket outlets provided is minimal. You may also be surprised that the lighting was barely enough in our today’s standard.

I have replaced some components with the actual components that you actually find in your house electrical panel today. Forty years ago the 6 Amps MCB was not available yet. The engineers and electricians used fuses. They worked just fine, but the MCBs (miniature circuit breakers) are better and they do not have to be replaced after each time a circuit trips.

Again these brief electrical tips are for real beginners of electrical wiring installation. If you are more advanced than that, then you have to forgive me for this boring lesson. You are welcome to the much more advanced materials in my other posts in this blog.

Now let’s start…

Refer to the three drawings below while you are reading this. Remember that these three diagrams must actually be read together. Picture 7 shows the basic house layout. A real house will have more than what is shown in this drawing, I agree. However we only put inside an electrical drawing is meant to help give the meaning to the electrical information that the drawing is supposed to convey. If the room’s purpose is adequately explained by just having its room name, then only the room name is shown inside the room in the drawing.

Even on big projects with the cost of electrical installation amounting to millions of dollars, that is still standard approach to the electrical layout drawings. If unnecessary information and details are also shown, they will contribute to the actual number of errors that happen during the actual installation of the electrical works.

Picture 7 – Electrical layout drawing for a small house electrical installation

This house have a few basic spaces (See Picture 7):

a) Starting from outside the main entrance, you have the car porch. That’s also part of the house space that need electricity. Look again to those pictures at Section A above (House Wiring Brief). At this house

b) At at the car porch you also have the electric meter panel which belongs to the electric supply authority or the electric supply company licensed by the government to supply and sell electricity to the public in that area.

c) Do you know where this meter panel is on the electrical layout drawing? If you don’t, then first you now need to learn about electrical symbols and how to interpret information on technical drawings, which are the electrical drawings in this case.

d) Now let’s go step by step. In Picture 8, you can see a list of electrical symbols with a little description for each one of them. At the bottom of the list is the energy meter symbol (symbol No. 10). Going back to Picture 7, you can see the same meter symbol at the house entrance to the left of the front door, right on the house front wall. You saw this meter inside Picture 1 and Picture 2 above. Of course it is not the same house, but the location of the meter is exactly the same. The height of the meter is a well above a level reachable by hand to place it out of reach.

e) Now you have seen the meter symbol in the list of symbols (Picture 8). You have located the meter at the front door inside the electrical installation layout drawing (Picture 7). You have also seen the actual photo pictures of the meter at a similar location in Picture 1 and Picture 2. I am quite sure you have actually seen these types of meters before with your own eyes somewhere even if your house does not have one. However it is Picture 9 that will set you on the path to the electrician’s world. That is the picture of electrical schematic diagram.

f) Together with the electrical layout, the schematic diagram lays out the overall system for the whole electrical installation. As to the kWh meter we just talked about, it is one of the high profile parts in the schematic.

g) Locate the meter at the bottom part of the diagram. Observe that the symbol used in this diagram is not the same as that in the electrical layout drawing. Why? Because the function and the nature of schematic drawings make it impractical most of the time to use the same symbol. You are right. We then need to make a separate list of symbols for the schematic diagram. That is actually a standard practice for many installations like the power station, control circuits, etc. However, for simple buildings and for houses, it is quite rare to have the list of symbols for the schematics. But it is absolutely alright to use one.

h) Still at the car porch, you can see the blue colored fluorescent light symbol with the red colored number 1 next to it. This is one of the standard symbols widely used for fluorescent lighting. Refer to the symbol list (symbol No. 2) for a brief description of the symbol. The description says “2 feet fluorescent light fixture, with one no of 18 Watt tube, ceiling mounted type.” What the description does not say is that the light fixture is also a bare channel type, which means it does not have any diffuser to envelope the fluorescent tube. You can see the tube, which may not be aesthetically very pleasing in some people’s opinion. However, this type of light fixture is very efficient in terms of the lighting lumens for every watt of electric energy consumed.

i) The red colored number 1 next to the light symbol is the circuit number. It is the identification number of which outgoing circuit breaker the lighting wiring is connected to in the electrical panel (i.e. the consumer unit, C.U.). Refer to the schematic diagram (Picture 9).

j) While you are on the schematic drawing, let me just explain a few items related to the lighting symbol and its wiring circuit number. The large rectangle with “Consumer Panel” label is a representation of the electrical panel or the house consumer unit. In some countries, it is also called the distribution board or the DB. All components inside the rectangle are the components mounted inside the panel (you can see the panel picture again in Picture 3 above). While lines shown connecting to the rectangle box are the electrical connections to the conducting parts of the panel. If it is shown as connecting to one of the components inside the panel, then an electrical connection is made to that particular component whether by cables, wires or other electrical conductors such as the earthing copper tape. For example, look at the lower right corner of the consumer panel rectangle. You can see a symbol with the letters “6 KA” next to it. That is the ground symbol with a connecting wire symbol. The connecting wire connects the electrical grounding to the electrical panel with a wire or other acceptable earthing conductor. The point where the wire symbol connects to the rectangle is actually in itself a connection symbol or a bonding symbol. Sometimes this connection symbol has dark black circle at the lines intersection to emphasize the need for a good electrical bonding. However, for some reasons this is not a standard practice in ordinary buildings wiring work.

k) Let’s just spend a few minutes on the schematic diagram to understand the system of the house electrical system, and also how to understand the schematic drawing. Look at the bottom part of the picture. The line coming up from the bottom has been labeled “AUTHORITY’S INCOMING LV CABLE”. This is where the system starts. The incoming supply cable may be running on electric pole as in Picture 1, or it may be underground cables. Whichever it is, that is what the line represents.

l) The line connects to the cutout fuse symbol on the meter panel rectangle. Again all components inside the rectangle are actually mounted on the meter panel. Altogether there are three components: the kWh meter, the cutout fuse and the neutral link. You may notice that the neutral link symbol is shown without connection. This is another aspect of the electrical schematic diagram that often confuses beginners. The electrical schematic is actually a single line diagram. It does not intend to show all the actual wires or cables. A line only represents the direction of flows of the electrical power, or the flow of a certain type of electrical current. Therefore, the line connecting to the cutout fuse shows the electric power flow from the supply authority’s cables to the house meter panel, terminating at the cutout fuse. The neutral link symbol is often shown on the drawing to show that the fuse is only installed at the phase wire. The neutral wire is only provided with solid connection, not a fuse. So when there’s a certain fault current condition that cause the cutout fuse to blow, then only the phase wire connection is broken. The neutral connection will still be present as normal. This method of drawing is also meant to show clearly the type of supply that is delivered to the house. In this case, it is a single phase, two-wire supply. From this angle, the neutral link is meant to show the neutral symbol, and the cutout fuse as the phase symbol. Remember that there are single phase, two-wire plus earth type of supply from the authority. This type has a 3-wire cable instead of 2-wire that we have here. The third wire is the earth wire. I will talk more about the third wire in my future posts.

m) From the cut-out fuse, the power flows to the meter unit on the same panel, and then leave the meter panel via an external cable to the consumer electrical panel, terminating at the 60-Amps switch fuse unit. The connection from the meter to the switch fuse is shown by a line, which generally shows a power flow connection. It can mean an armored 3-core cable, or two cheap PVC-type cables or just a simple copper tape conductor connection. More detail information on the connection is usually provided by the labels that have been provided. In this case, a label “2-25 SQmm PVC/PVC IN CONCEALED CONDUIT” has been provided. That label is saying that the power connection is made by two lengths of single-core PVC-insulated, PVC-sheathed cable, and the cables are installed inside a conduit that should be concealed. Concealed where? Well, that is for the electrical contractor to solve. As far as the design is concerned, the conduit carrying the PVC cables must be concealed. It can be inside the house brick wall, or the contractor may just hide it above the ceiling. Or a combination of both methods.

n) From the switch fuse unit, the power flows to the ELCB or the earth leakage circuit breaker. The ELCB symbol may seem very simple, but inside it the component is a system by itself. This device is not explicitly shown on the electrical layout drawing. It is part of the electrical panel just like the switch fuse and the outgoing MCB (miniature circuit breakers). You can read more on how the ELCB works in my post on electrical shock protection. However I have included here the typical schematic construction of the ELCB for your easy reference (Picture 10).

o) A small note on the typical ELCB schematic in Picture 10: Observe and study a few other electrical symbols in the picture that are not available in the electrical schematic diagram and the electrical layout drawing: the load symbol (at the right side of the drawing); the fault symbol (inside the load symbol); another type of breaker symbols (the trip circuit breaker symbol on the left); the neutral symbol and the phase symbol (at the supply side on the left); the test pushbutton switch symbol, the trip coil symbol and the search coil symbol. Observe also another type of grounding symbol at below the load symbol.

p) Note that the trip circuit breaker symbol looks like a combination of a switch symbol and the trip coil symbol. I will explain more about this on other posts. With all these symbols inside the ELCB circuit, you can safely say that the ELCB symbol is a circuit symbol, an electrical sub-system by itself.

Visit this post, ELCB circuit, to read in more details about this shock protection device.

q) From the ELCB the power flows to the busbars (the horizontal lines) to be distributed to individual outgoing circuits. Each of the outgoing circuits is protected by a 6A SPN MCB or a 20A SPN MCB (miniature circuit breaker). Each of the outgoing circuits has also been given an identification tag, represented by the numbers 1 to 6 in side a small circle at the end of each outgoing lines. This is the number next to the 18W fluorescent lighting symbol at the car porch in the electrical layout drawing. So when you look at the layout drawing you know from which circuit breaker the supply is taken inside the electrical panel. This way a repair electrician knows exactly how to troubleshoot without wasting too much time. During a new installation work, the installation electrician knows exactly how the electrical designer wants the wiring to be done. This is very important because different buildings may have different functions that will affect how the electrical system is to be wired. With this method of conveying the requirements to the electrician or the contractor, the owner of the building or the installation will get exactly what she pays for.

r) Notice that next to each circuit identification number on the schematic diagram a brief description is given to describe briefly all the loads connected to that circuit. Again in the case of outgoing circuit no. 1 above, you can see that “3 NOS 1 x 36W (F) & 1 NO 1 x 18W (F) & 2 NOS C/FAN” is connected to this circuit. With this information, it can be quickly checked whether the wiring cable size to supply total loads is adequate. The cable size itself is also clearly shown there with the labels and the tag lines. In this case our 18W fluorescent circuit is wired with 2 PVC-insulated wires of 1.5 square millimeter in side a metal conduit and all metal parts of the light fixture are connected to earth by a third wire of the same type and size. So at least 3 wires will be connected to this fixture. That is what is meant by the label “2-1.5sqmm PVC + 1-1.5sqmm E IN G.I. CONDUIT”.

s) With that you now understand the electric power flow, also the part and component information that the schematic diagram intend to convey. Before I close this paragraph on the diagram, one more thing I need to highlight. Look at the schematic again and observe that there seem to be two busbars supplying current to the circuit breakers, and the second busbar are connected through a second ELCB. Notice also that the labels to both ELCBs are almost same - 60A DP (100 MA) – with a minor difference – the second ELCB has “(30 MA)” label instead of “(100 MA)”. What it says is that both ELCBs are rated at 60A, and both are two pole type (the DP label is a double pole symbol, the two pole symbol, or 2 pole symbol). However the first ELCB has its sensitivity to earth leakage current set at 100 miliamperes, while the second ELCB is set at 30 miliamperes.

t) Why? I am sure this “why” has so many branch questions inside the big one, and if I go further it will develop into another big topic that will distract us from the present topic. So I will have to dedicate a separate post in the future for it. For now just observe that the second ELCB actually feed currents to circuits supplying only the socket outlets. All 13A power sockets in the house are supplied from this busbar and given a more sensitive (therefore better) shock protection setting. The first ELCB on the other hand feeds power to all other electrical fittings and fixtures including the lighting and the fans. If you install a 4 kW water heater to the house toilet, it should also be supplied from the 100 mA ELCB, and never from the 30mA one. This is actually a deeper issue on the electric shock protection. If you cannot wait for my next post, then feel free to read on the electric shock protection in one of my earlier posts.

u) Now let’s go back to the electrical layout drawing (Picture 7). We were talking about the two-feet ceiling mounted bare channel 18W fluorescent light fixture at the car porch when we left for the schematic diagram. I am not yet done with this light fitting because there one last piece of information I have not yet explained related to this fitting, which is the red dotted line with arrow symbol coming horizontally from the 18W light symbol, and turns 90 degree towards the main door. This is actually a wiring symbol for the light fitting and the arrow actually points to the direction of the control switch for that light. Inthis case the switch is licated on the wall just inside the main door. The switch symbol is in blue color near the red colored consumer electrical panel. Refer to symbol No. 7 in Picture 8 for a better view of the switch symbol and the brief description.

v) Notice also the speed regulator and switch symbol for the ceiling fan just next to the light switch on the wall. As you observe the location of the electrical symbols on the layout you will gradually understand and rationalize yourself how they are laid out. One last item I wish to touch on the layout drawing is the socket outlet symbols. Notice how they are laid out and the circuit number of the circuit that are feeding them (Recall the outgoing circuit number on the schematic diagram). Take note that for the 20A circuit breakers used in this design, two 13A socket outlets are basically the maximum number that can be connected to each of the circuit breakers. While in the case of the 5A circuit breakers for the lighting and ceiling fans, each circuit breaker can handle up to ten lighting and ceiling fan points per circuit.

w) Now you already know how to read the electrical drawings. If you go from component to component on the drawings and try to relate them to the house wiring brief that I give in Section A, you will have the overall full picture of the typical electrical installation for a simple house like the one illustrated by these drawings.

Picture 8 – Legends and symbols for electrical installation drawings.

Picture 9 – Wiring schematic drawing

Picture 10 – ELCB circuit

SECTION C : Simple checking

Our home is supposed to be a very safe place for our children and our family, but it is far from safe if we never make some effort to ensure the electrical system in the house is really safe.

The following simple guide can be used to quickly check the electrical installation in your home. This check can be done simply and it does not require much electrical skills.

When you feel you have found something that is not right with the electrical installation in your home, then a qualified electrical contractor can be called in to do a more detailed inspection and carry out the repair works if necessary.

Plugs and Socket Outlets

Check around the house for switches, plugs and socket outlets that seem to have cracked, worn out or abused, blacken or loose.

An electrical plug that seems to be loosely fitted into the socket outlet can easily get overheated and eventually start a fire. Usually this happen to a socket that has been worn out or abused, and it is about to expire soon. Do not use this socket if possible and get it replaced as soon as you can.

Any outlet that has a damaged or broken wall plate must be repaired or replaced immediately. Prevent access to unused electrical sockets from children by putting safety covers. You can usually purchase these covers from any electrical store.

Ensure that an electrical plug can fit the socket outlet you intend to use it with. If a plug does not fit an outlet, do not force it. Do not remove the ground pin of a plug to make a three-pin plug into a two-pin one. This will eliminate the grounding and it can cause electrocution.

Do not overload a socket outlet. If you connect too many electrical appliances to a single socket outlet, the socket can silently overheat and start a fire. An extension cord with multiple outlets connected to this socket cannot prevent the overheating problem. So don't do it if possible.

If you find a socket or light switches that give out a hissing sound, then it's the clear sign that's it's about to expire soon and it can take the whole house with it. Do not use it. Get it repaired immediately.

Wiring, Electrical Cords and Extension Cords

If your house is an old one, look around the house for wiring works that seem to have aged or the insulation has shown signs of being cracked. The worst areas would probably be in the kitchen or the basement if the house has one. If you can see these signs then the wiring in those areas may already need replacement. Call a qualified electrician to assess the situation and decide whether a rewiring work is necessary.

Extension cords seem to have become so indispensable in all homes that there hardly is any house that does not have one. They are so useful and so flexible. However, they are supposed to be just temporary measures. Do not use it like it is a permanent electrical wiring. Take the cord off and keep it at proper storage after each use.

Do not run the extension cords under carpet, rugs or other heat insulating materials. It can silently overheat and start a fire.

Also avoid running it across traffic areas in the house and do not rest any furniture on them. The cord outer sheath and the insulation of the internal wires can get damaged making the risk of electrical shock more likely.

When using extension cords always keep in mind the current rating of the cord wires. Do not overload it. Having a cord with just single-outlet instead of multiple-outlets can greatly help prevent overloading. The socket end of the cord is usually a distance away from the closest wall socket, so users tend to conveniently connect everything to the multiple sockets. You can effectively discourage this behavior by having just one socket.

Appliance electrical cords must always be checked for any sign of damage or overheating. Due to the proximity of the electrical cord with the equipment itself, it usually suffers from overheating. The bending damages are usually caused by bending at tight spots and being rested on by the appliance itself. If the cord seems cracked or brittle, then it is time to get it replaced with a new one.

Earth Leakage Circuit Breakers (ELCBs)

The earth leakage circuit breakers or commonly called ELCBs are located inside the home electrical panel or distribution board. This component of the home electrical installation is designed to detect any leakage of electrical current.

This so-called leakage current occurs when there are some defects in the performance of some parts of the installation. These defects can be caused by faulty parts or by injuries to the insulation of the wiring, cables, electrical appliances or other accessories such as the switches and socket outlets.

When the current leakage occurs, the ELCB then trips the electrical supply within a a fraction of a second after the leakage has been detected. Therefore any possibility of electrical shock to persons who are in contact to the electrical installation at that particular moment is avoided. (Visit this post, How you get electric shocks, to understand better how electric shock accidents occur.)

The use of ELCB in house wiring is required by law and omitting it is a serious offence under the electricity supply act.

Other names are also used to call the ELCBs, the most common being Residual Current Circuit Breakers (RCBs), Residual Current Devices (RCDs) and Residual Current Circuit Breakers with Overcurrent (RCBOs). The difference in names is meant to show some difference in the design used in their manufacture. The purpose and operation of the parts are all the same. So do not be confused when they are the ones installed at your house electrical panel.

The ELCBs can usually be simply tested by a Test Pushbutton on the unit itself. It is recommended that the ELCB be tested once a month and after every thunderstorm to make sure it is still working properly.

Visit this post, ELCB - Home Electrical Shock Protection, to read more about the earth leakage circuit breakers.

Lamps and Light Bulbs

It is usually very easy to fit in a light bulb of higher rating into an existing light fitting at home. However this is a very dangerous practice. There has been countless number of fires that have been started by light fittings fitted with higher rated bulbs. Always make sure a new bulb to be installed is not of higher rating than originally designed for the fitting.

Do not assume that the wattage of the burnt out bulb to be replaced is the correct rating. It might have been wrongly substituted during the earlier replacement of the bulb. The wattage of the fixture can be found somewhere on the fitting. Check it personally. If you are still not sure, just give a call to the manufacturer of the fixture. It is always better to be safe than sorry when it comes to electrical matters.

When fitting in the new bulb, always make sure it fits in or screwed in tightly. A loosely installed bulb also can cause overheating and start a fire.

Give special attention to halogen lamp if you use one. This type of lamp operates at a much higher temperature than a normal household filament lamp. Keep a halogen lamp a few feet away from nearby combustible materials and clothing. Always turn it off whenever you leave the room unattended.

If possible do not use this type of lamps inside children's bedroom.

DB Fuses and Circuit Breakers

Fuse and circuit breakers are the major components inside the home electrical panel or distribution board (DB). The ratings of the circuit breakers and fuses are selected specifically for the purpose of protecting the wiring cables running throughout the house.

When you have to replace a fuse, never replace it one of higher rating. Otherwise the wiring cables may get overheated and ignite a fire first before the fuse actually trip. If you do not know how to choose the correct fuse size or you cannot get the specific rating that you are looking for, get a qualified electrician to do it. Do not take shortcuts.

If the fuse is of the rewirable type, replace it with exactly the same size and wire type. If you are not sure enough, call the electrician. The risk to human safety is too high for you to play trial-and-error on house wiring.

Circuit breakers are better than fuses for a home DB for the very reason that that it does not have to be replaced after each tripping. Then the question of replacement with a wrong rating does not arise. However make sure to sufficiently check the tripped circuit before turning the circuit breaker back to the ON position or you will risk totally damaging the appliance or the accessory causing the tripping.

Home Electrical Equipment and Appliances

When the ELCB keeps tripping or a fuse repeatedly blows, then it is a sign that there is something wrong with the appliance being used. It is also possible that the switch or the electrical socket outlet is faulty. Have them properly checked and repaired.

Make sure all electrical appliances, home personal computers and all other entertainment equipment (i.e. video games) in the house are in good conditions and working properly.

Check the wiring, electrical cords, plugs and socket outlets for any sign of cracks or damage.

If surge protectors are used for any or the appliance and the electrical equipment, always make sure the surge protectors carry a certification recognized by the relevant national certification agencies.

If you use space heaters in your home in cold climates, make sure the heaters are located a few feet away from any combustible material like clothing, bedspread or rugs. Never use them in rooms where children are not supervised.

When you use space heaters, do not share the socket outlets with other appliances. Do not use extension cords. Always plug it directly to permanent socket outlets. Turn it off and unplug it when not in use.

Outdoor Electrical Safety

Overhead wires are one of the common methods of electricity distribution in residential areas. So when you use a ladder outside the house, always watch out for these overhead wires and power lines.

If you use electric powered movers or other tools, never use them in the rain or in wet situations like water ponding lawn or wet grass. Periodically inspect all these tools and equipment for any sign of damage to the extension cords, damaged plugs or appliance housing. These sorts of defects can easily cause electrical accidents and electrocution.

If you use extension cords, make sure it is rated for the outdoor use, of the weatherproof type and they are still in good condition. A damaged waterproof cord and socket may seem to be working properly until accident happens. Then that will already be too late.

When not in use, unplug and keep safe all these equipment including the extension cords.

Keep Them Away From Water

Keep all electrical appliances, the electrical cords and the electrical extension cords away from water and wet environment. If an area inside the house becomes wet, unplug all these things and move them away.

Never try to save an electrical appliance that has fallen into water even if it has been turned off. Isolate the whole electrical power at the DB first. Then unplug the appliance. Then only pull it out of the water.

Do not use the appliance again until a qualified repairman has checked it.

Note: If you are looking for pictures of electrical installations, visit this post, Free electric installation pictures. I have linked it to various posts that contain pictures.

© Copyright http://electricalinstallatioblog.blogspot.com All rights reserved - Home electrical wiring, symbols and checking.