Photo 1 - Electrical services inside a building

Jokes aside, actually I received a few emails from some friends in the education business (i.e. local universities) complaining that they like the real construction pictures and the temporary electrical installation pictures that I uploaded to this blog (visit the anchor post here, Temporary Electrical Installations).

However, the pictures are scattered all over the place. A few of them suggested that I put these pictures into one post and the same for the electrical schematics.

I know these people wanted to use these photos and electrical diagrams for their teaching works. Part of me feels the reluctance to this step because I know these real construction photos have some monetary values.

If I locate them at one place, then many readers who are hunting for these photos will just go to the page (this page actually) and just save it. They may not read other pages, which I have some advertisements placed there. I may lose my commissions.

But what the heck, I uploaded all these things for the benefit of the readers anyway.

So I have decided to grant their requests. I am not going to insert all these photographs today. But I will do it gradually because it takes time. I will not just insert the pictures into this page, anybody can do that. But I will add some comment to each of the pics so there will be some information that goes with each picture.

A picture may say a thousand words, but they may be in languages you do not understand. So I need to attach some comments and that will take a little time and thinking. I am not a writer by nature.

Okay, enough talk. The first pictures are about fireman switch installation.

Enjoy.

Picture 2 – Fireman switch installation

Picture 3 - Fireman switches for high-rise buildings

For readers without electrical background, these are the emergency electrical isolation switch installed and to be used by the firemen when they want to fight fire the building.

EMERGENCY LIGHTING INSTALLATION PICTURES

Most countries have statutory provisions that require the installation of emergency lights in all buildings exceeding certain sizes. These lights need to be provided at strategic locations throughout the building to assist in the evacuation of the building occupants during fire situations or other types of emergencies.

Practically this emergency lighting is useful even without the emergency and during daytime. When the mains power fails, there is a certain time delay before the backup power supply can take over. The standby electric generator, the most usual form of backup emergency power in normal buildings, take quite second to get warmed up and provide the supply to essential services inside the building.

Some internal corridors in large buildings can be very dark without electrical lighting. Serious accidents can happen if the corridor suddenly becomes dark. Even with a little stray lights from windows somewhere, the eyes take a little bit of time to adjust to the sudden change of light level.

Some internal rooms inside air-conditioned buildings are totally windowless. Even with windows, the daylight from outside the building may not reach the rooms. During power failures, these rooms can be darker than nighttime out in the open air outside. At least outside there you can rely on a little light from the stars or the moon. Again, in this type of darkness, anything can happen.

The self-contained emergency light fittings are usually installed at all exit routes and at all places where uninterrupted lighting is required. In the second situation this lights serve the dual functions of a fire related equipment and a normal lighting (with much reduced lighting level).

The emergency light fittings are connected to the essential supply of the building electrical system. This way the rechargeable storage battery is charged even during normal power failure (i.e. when the standby electrical generator is running).

You can read more details on this issue at my other post, emergency lights installation.

Today I have uploaded few pictures showing the method of installing a ceiling-recessed emergency lighting (EL) unit. This work was photographs at a high-rise building construction a few months ago.

As far as the choice of types of the EL light, I would personally prefer a surface mounted self-contained type. The one being installed in this picture is also a battery-backed self-contained type, but it is recessed mounted.

You can see below two pictures showing how a ceiling-recessed emergency light fitting is being installed. There are more pictures of the installation that you can see at this post, Emergency light installation pics. I did not link all the pictures to this post because that will make this post too long after a while.

This post will also be the main page for all the pictures that I uploaded to this blog. If I link all of them here, the page will also take too long to download. People with slow connections may have problem downloading this page.

Picture 4 – Side view of the ceiling-recessed emergency light installation

Picture 5 – Top view, from above the ceiling panel, to show how it is fixed to the board

Picture 5 – Top view, from above the ceiling panel, to show how it is fixed to the board

Cable trays and cable ladder pictures

I have uploaded a few pictures and a diagram on the installation of electrical cable trays and cable ladders for those who have some need for them.

You can see all the cable tray pictures at this post, Cable tray and ladder installation.

If you are looking for pictures on cable ladders, I have uploaded one at this post, Electrical cable ladder pictures. More pics will be coming soon.

At the end of these pictures, you will also find a sample specification for the cable tray and cable ladder installations in multi-storey office buildings. If you wish to see more photos of electrical installations, visit my other post, Electrical installation pictures.

Picture 6 – Cable tray at high level inside a chiller plant room

Cable trays for the installation of electric power cables are usually specified as perforated hot-dipped galvanized sheet steel.

The term perforated usually is defined as holes provided to the sheet of the trays to allow the movement of airflow that can provide a more natural flow of air circulation around the electric cables. This air movement can effectively help cool the cables on the tray.

All electric cables carrying current dissipate some power because of the resistance of the current carrying conductors.

If the energy dissipated in the form of heat is not carried away from the cables, the cables will heat themselves up and effectively operate at the higher temperature than the actual surrounding air. This will lower the actual maximum current that the cables can actually handle.

This IEE Regulation provides a table of current carrying capacities of cables that are run on perforated cable trays. However, these cable ratings are only applicable if the holes occupy at least 30 percent of the surface area of the trays.

Photo 7 – Underground electrical ducts crossing a roadside drain

Today I have uploaded a few photographs of underground cable ducts crossing a roadside drain at a project site a couple of months ago.

A good design of external electrical works would have considered the situations where all the different services would cross each other.

Even when they do not cross each other, the space where all the services need to be installed may become smaller or narrower.

Therefore a good design engineer need to foresee these potential problems that may be too difficult or too expensive to be solved by the trade contractors, engineers and managers during the construction stage.

In some construction environments, all designs from the respective design consultants and engineers would be passed through a coordination stage. There the detailed design drawings are superimposed over each other.

Read the full article at this post, Cable ducts crossing roadside drain.

Photo 8 – A switch center at a small meeting room

The following materials can be used as a performance specification for installation of socket outlets and switches in multi-storey office buildings. I will also add some pictures of actual installations of these devices in future, and may be also some drawings and diagrams. Come back and check out this post every few weeks.

Read the full article at this post, Socket outlets and switch installations. There are more photos at this post also, Metalclad electrical sockets.

Photo 8 – Armored XLPE cables and fire rated (FR) cables on cable tray inside an electrical riser shaft

The following sample specifications cover the installation of PVC, XLPE, PILC and MICC cables in a new high-rise office building. Read the full article at this post, PVC PILC XLPE MICC cable installation .

Photo 9 – Armored XLPE cables on cable tray

One length of underground armored cable is used. Underground means the cable is installed inside the ground about 3 ft below the surface.

Armored cable cost much more because of the steel wire armor protecting the cable from physical damage. The letters SWA in the cable tag “XLPE/SWA/PVC” is an acronym for “steel wire armor”.

“XLPE” at the front means the insulation of the cable conductor. When we say a cable, the terminology is actually not precise enough.

In this case, inside the incoming supply cable there is actually 4 inner cores each with an electrical insulation. Therefore, each of the four insulated inner cores (the inner core is usually made of either copper or aluminium) is a complete electrical cable by itself.

The four of them are bunched together to make it easier to run and it can reduce the cost. We can actually use 4 independent cables instead of one cable with 4 inner insulated cores.

Read the complete article at this post, Intro to XLPE armored cables.

Photo 10 – Wall-mounted surface conduit

The above photo shows the distance between two draw-boxes in a surface-mounted conduit system. Click here to go back to electric conduit installation.

The photograph shows two metal conduits run on the surface of a wall. Here I just wanted to show the distance between the two draw boxes on the upper conduit. This maximum distance should be 9 meter if the requirements of the specifications are to be strictly followed.

Read the full article at this post, distance between conduit draw boxes.

Photo 11 - The continuous ring type of identification ferrules

This type of wiring identification material has been around for some time and it is still widely used. Each of the letters of the identification tag requires one piece of the ring.

So if the wiring identification number contains 6 characters of letters, then 6 pieces of the rings would be required.

Needless to say, the task to install these type of identification ferrules can be quite tedious and time consuming. It is simply an additional cost to the cost of the DB.

Read the full article at this post, DB wiring identification ferrules. However, this article is just a supplement to a previous post which was actually a sample specifications, Electrical DB wiring.

Photo 12 - View of the lower part of a main switchboard

You may be wondering why I did not stand back a little bit and take a wider view of the subswitchboard. The would give a nicer picture, right?

I however took this picture when the main switchboard (MSB) has already been located on its actual position in the electrical switchroom (LV Switchroom).

Usually the layout of an electrical LV room is such that the main switchboard is located near the wall of the room. The space behind the board is usually between 600mm to 1000mm between the back of the switchboard and the wall.

In fact 750mm is a more common space clearance for office and residential building. This of from my own personal experience. I do see projects where the architects were more generous.

In those cases you may then find that the clearance is between 1000mm to 1300mm.

Read the rest of the post here, Switchboard earthing busbar. There is also a simple performance specifications on this topic (Switchboard electrical earthing) for readers who need it.

Photo 13 - A switchboard being unloaded from the transport at a construction site of a building project

Switchboards are the switching centers of the low voltage distribution sytem. They are also the places where the control and protection system is located.

Because of the importance of these equipment, all aspects of a switchboard installation need to be closely monitored. Even the loading and unloading of them to and from the transport need to be monitored.

Read the rest of the post here, switchboard installation check.

Photo 14 – 13A switched socket outlets inside underfloor junction boxes

The above is a picture of two units of under floor service boxes with 13A switched socket outlets installed.

Is there any problem here?

I took this picture some two or three years ago. Shown in the picture are two service boxes for an underfloor trunking system.

For the benefit of readers who are not very familiar with the term underfloor trunking, underfloor junction boxes, and underfloor service boxes and how they relate to each other, please refer to the layout drawing below.

Please visit the post, 13A sockets inside underfloor box, to read the rest of the article.Image 15 - 4 ft 36 Watt Wall-mounted Fluorescent Light Symbol

For readers who are looking for a simple house electrical symbols, you may wish to visit this post, House electrical symbols. I have uploaded a list of symbols for a small house.

This post, Home electrical wiring, symbols and checking, is the original post. It is very long. That's why I am trying to break it up into smaller posts for the the benefit of readers who are looking for the information contained in the long post.

This post on electrical symbols is the first of such posts.

Image 16 – The electric meter panel symbol

The above image on meter panel comes from the second small post. This time it about a simple house electrical schematic. Read it here, Simple house electrical schematic.

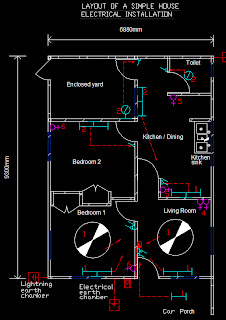

Drawing 17 – An electrical layout drawing for a two-bedroom small house

I just uploaded this simple electrical layout for a small two bedroom house. You can read the rest of the article at this post, Simple house electrical layout.

Picture 18 – An earthing rod installed inside a precast concrete inspection chamber

The above is a picture of electrical earth rod inside an inspection chamber. This is a copper-jacketed steel rod with 16mm diameter.

The earthing system at this project was not yet completed at this point time.

However, the project was nearing the end of the construction period. Since this earth rod inspection chamber was by the side of a service road near the plant-room area, the installation of the rod and chamber needed to wait until the road crusher run has been laid.

This is to make sure that the chamber can be properly set to the finish level of the road.

Here the rod and chamber were already in place, just waiting for the final tar coating.

See more pictures of eartg rods here, Copper earth rod pictures. There is also a simple specifications for installing electrical earthing system for high voltage substations at this post, Electrical earthing system.

Diagram 19 – Fault current path

While we are on the subject of electrical grounding, the above is a current path diagram that I did for an article about electric shock protection some time back.

It was a long article. Not pretty but it sure does have some real information if you need some. Read the article at this post, Home electrical earth installation.

Diagram 20 – A ground floor layout of building services

I just sent an article about electrical risers at this post, Electrical riser rooms.

There was also an article about electrical risers that I sent some time ago at this post, Electrical rooms design. However, this is more of an overview of the design planning for electrical rooms.

Part Drawing 21 – The lift motor room layout drawing

I just sent an article about electrical risers at this post, Electrical riser rooms.

There was also an article about electrical risers that I sent some time ago at this post, Electrical rooms design. However, this is more of an overview of the design planning for electrical rooms.

Part Drawing 21 – The lift motor room layout drawing

This is a lift motor room layout for an eight storey hostel block. I uploaded part drawing this as materials for the discussion on electrical rooms design.

Read the post here, Lift motor room layout drawing.

Picture 21 - Neutral link of main incoming circuit breaker

Electrical fuses and neutral links are among the most commonly discussed items on consumers’ discussion forums such as Yahoo Answers, etc.

Many times, the higher the number of people who gets involved in a trying to answer a simple electrical question, the more confused the issue becomes.

Instead of understanding more, many beginners often get confused and sometimes misled.

A few pictures or diagrams could have made a significant difference to the beginners who were trying to understand some basics of electrical installations. But then I guess many of those forums do not provide facilities for attachment of graphics.

Read the full article here, Neutral link pictures.

Copyright http://electricalinstallationblog.blogspot.com/ Free electric installation pictures

No comments:

Post a Comment

Note: Only a member of this blog may post a comment.