Photo 1 – Armored XLPE cables on cable tray

In case some readers are confused why I give lengthy basics on the electrical engineering in this blog, please be reminded that this blog is intended for beginners.

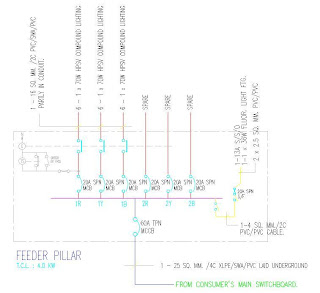

Diagram 2 – Schematic diagram for a small compound lighting feeder pillar

I always like to use schematic diagram of street lighting or compound lighting feeder pillar when I need to use a single line schematic to explain about cables.

That is because many of the other players (the architect, construction managers, quantity surveyors, landscape designers, etc) on a construction site can easily connect to a compound lighting feeder pillar.

The single line diagram is also simple enough for people without electrical training to understand with additional assistance.

Diagram 2 above show one such feeder pillar single line diagram.

Since this article is about cables, I will only explain about the cable parts of the schematic. I will explain on other parts in future post.

The cable

Here the XLPE cable is used as the incoming supply cable to the feeder pillar. One length of underground armored cable is used. Underground means the cable is installed inside the ground about 3 ft below the surface.

Armored cable cost much more because of the steel wire armor protecting the cable from physical damage. The letters SWA in the cable tag “XLPE/SWA/PVC” is an acronym for “steel wire armor”.

“XLPE” at the front means the insulation of the cable conductor. When we say a cable, the terminology is actually not precise enough.

In this case, inside the incoming supply cable there is actually 4 inner cores each with an electrical insulation. Therefore, each of the four insulated inner cores (the inner core is usually made of either copper or aluminium) is a complete electrical cable by itself.

The four of them are bunched together to make it easier to run and it can reduce the cost. We can actually use 4 independent cables instead of one cable with 4 inner insulated cores.

The XLPE label mentioned above indicates the type of insulation of each of the inner cores.

When these cores are bunched together in a bunch like these, an outer insulation is again extruded or layered over the whole bunch, making it look like a single cable. It is actually 4 cables that are bunch together.

The outer insulation is called outer sheath.

If this cable is to be installed underground, it is always better and always considered necessary to provide something strong over the cable in case an excavation work accidentally hits it.

That is why the steel wire armor wrapped around the cable spirally all along the cable length. The armor protects the cable physically.

Then in order to protect the armor against corrosion and other degradation, another layer of insulation is applied over the steel wire armor. Most of the time, it is of PVC (poly vinyl chloride) materials.

That is the label “PVC” on the right of the cable tag.

I did not finish the XLPE part, did I?

What is XLPE?

The XLPE is just like the PVC, but is more expensive and of better quality. That is why it is used only at the inner core of the cable. The PVC material can be used instead of the XLPE, and it will work just fine.

But with XLPE, the inner cores can usually carry higher current for the same inner core size.

What is “1 – 25 SQ. MM. / 4C”?

“4C” – I just explained above, the 4 inner cores. If there are 5 or 3 cores inside, then it would have been 5C or 3C accordingly.

“25 SQ. MM.” – I mentioned about the size of each inner core, the copper or aluminium material underneath the XLPE insulation. This is the size. It is always in the form of net or real cross-section area. This means if an inner core is constructed of several smaller cylindrical copper wires, then the total cross-section area of those individual wires is taken and used to indicate the size in square millimeters.

I am following the British or European Standards here.

“1 – “ … well this mean one length of the 4-core cable is used here. We can use 2 lengths which will give us 8 cores of same sizes. They are installation conditions that may force us to do that, which is a more advanced topic. In that case, it would have been written like this:

“ 2 – 25 SQ. MM. /4C XLPE/SWA/PVC”.

As I said this post is just a short introductory brief on armored XLPE cables.

Click here to go back to the previous post, PVC, PILC, XLPE and MICC cable installation.

Note: This anchor post, Free electric installation pictures , may contain a summary of the materials you are looking for. It can be faster than clicking through each post title at the Blog Archive. I started it long ago but never actually got around to finish it.

Copyright http://electricalinstallationblog.blogspot.com/ Intro to XLPE armored cables